At KSA Crash Lab, our Material Testing services provide critical insights into the physical, mechanical, and chemical properties of the materials used in your vehicle components. Before a part is assembled or a prototype is built, we make sure the material behind it can perform under pressure.

What is Material Testing?

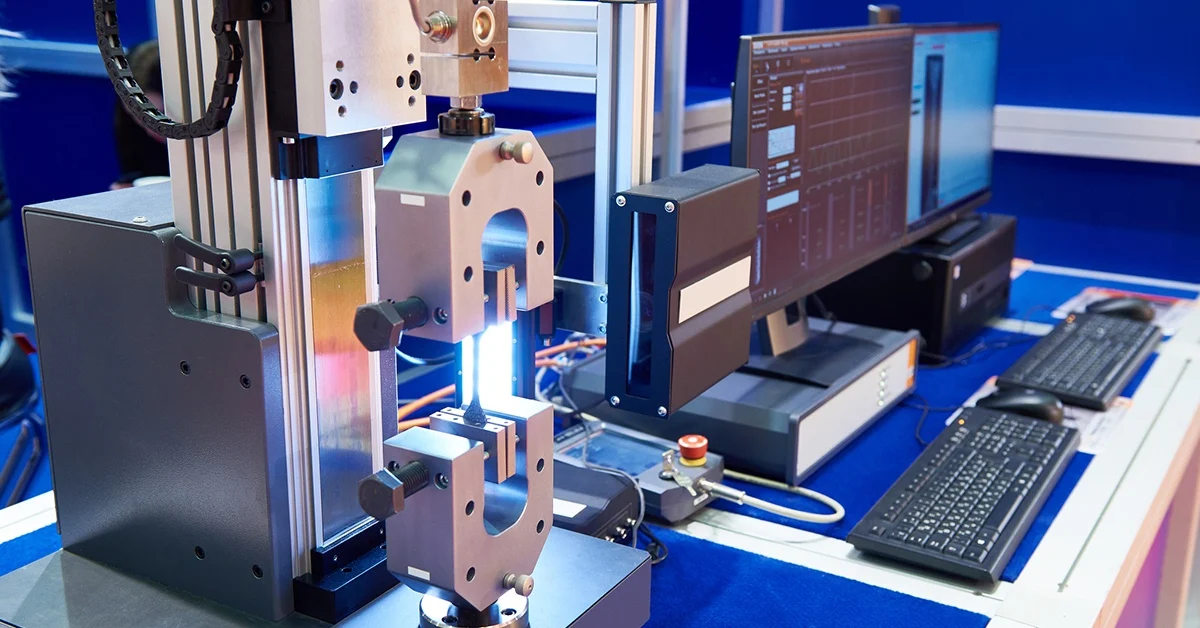

Material Testing is the process of evaluating the physical, mechanical, thermal, and chemical properties of materials to ensure they meet required performance, safety, and durability standards. It helps engineers and manufacturers verify that the selected materials can withstand real-world conditions such as stress, impact, fatigue, and environmental exposure.

Why Material Testing Matters؟

Every component’s safety, durability, and performance begin with the material it’s made of. From metals and composites to plastics and foams, understanding how each material behaves under stress is essential for:

- Crash energy absorption

- Structural integrity

- Heat and chemical resistance

- Weight reduction and fuel efficiency

- Long-term durability under vibration, fatigue, or load

Our Material Testing Capabilities

- Tensile & Compression Testing

Evaluate strength, elasticity, and breaking points. - Hardness Testing (Rockwell, Brinell, Vickers)

Determine resistance to surface deformation and wear. - Impact Testing (Charpy / Izod)

Measure how materials absorb energy during sudden impact. - Fatigue & Durability Testing

Assess how materials withstand repeated stress cycles. - Thermal & Environmental Testing

Simulate heat, cold, humidity, and chemical exposure over time. - Flammability & Burn Rate Tests

Ensure interior components meet fire safety regulations.

Materials We Work With

- Steel and aluminum alloys

- Polymers and reinforced plastics

- Foams and energy-absorbing materials

- Composites and hybrid structures

- Adhesives, rubbers, and sealants